Today, traditional frames have survived only in off-road vehicles, designed to move in harsh conditions, in which they are exposed to extreme loads. On the other hand, the supporting framework is increasingly being used, screwed to the body using flexible connectors, facilitating the distribution of forces in the structure and simplifying the technology of mounting chassis and powertrain assemblies. They also participate in the process of absorbing and dissipating the energy of the collision.

Today, traditional frames have survived only in off-road vehicles, designed to move in harsh conditions, in which they are exposed to extreme loads. On the other hand, the supporting framework is increasingly being used, screwed to the body using flexible connectors, facilitating the distribution of forces in the structure and simplifying the technology of mounting chassis and powertrain assemblies. They also participate in the process of absorbing and dissipating the energy of the collision.

In addition, a cautious return to semi-carrying structures can be observed, with additional composite frames which are, although an integral part of the bodywork, but relieving the hull to some extent from the transfer of loads. In sports cars, truss frames are found in the form of spatial systems welded from pipes and fittings.

Typical front subframe (Mercedes Viano) is welded from pressed steel elements and screwed to the body using flexible joints, dampening vibrations from the surface. The engine is attached to the frame, suspension and steering. Its use facilitates installation and possible post-accident repairs and relieves the supporting structure from dynamic loads, as well as enables better distribution of collision energy.

The Opel Astra II uses a front subframe shaped by hydroforming from one part, and not, as usual, welded from steel stampings. The starting element is a pre-bent seamless steel pipe. After subjecting it from the inside to water pressure and giving the final form by proper compression, the ends of the pipe are welded. The finished frame has a mass of 3,5 kg less than a traditional solution, and at the same time is characterized by greater strength and better ability to absorb impact energy. Participates in this process, mediating together with the stringers in the introduction of forces into the structure of the rigid passenger segment.

The body shell of the Astra II has a weight 230 kg and torsional stiffness above 6880 kNm/rad.

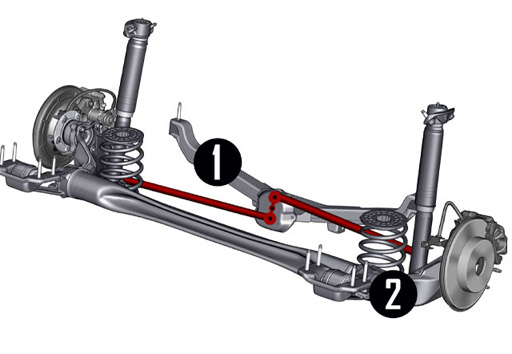

BMW cars have a rear subframe made of AlMg3.5Mn light alloy, supplied by the specialist company VAW aluminium AG. Its mass is about 36% smaller than steel. Performs similar functions as the front subframe. In its production, the method of hydroforming and bending linearly welded aluminum pipes is used. This reduces the number of parts that make up the component and allows tight execution tolerances to be met. The width of the gap between the welded edges is 0,5-0,7 mm. This solution is cheaper than extrusion technology, drawing and straightening profiles while maintaining the same or even higher strength parameters.