Combustion conditions can be optimized by breaking down the hydrocarbon groups sticky in the fuel into smaller molecules, which will easily combine with oxygen. This can, for example,. get through magnetic activation. After magnetic activation, the fuel is polarized and positively charged. The "sticky" groups of hydrocarbons are broken down, and smaller molecules have better access to oxygen. Thus, optimal conditions for the combustion of the mixture are created, which determines fuel consumption and has an impact on the amount of carbon monoxide and hydrocarbons in the exhaust gas.

Combustion conditions can be optimized by breaking down the hydrocarbon groups sticky in the fuel into smaller molecules, which will easily combine with oxygen. This can, for example,. get through magnetic activation. After magnetic activation, the fuel is polarized and positively charged. The "sticky" groups of hydrocarbons are broken down, and smaller molecules have better access to oxygen. Thus, optimal conditions for the combustion of the mixture are created, which determines fuel consumption and has an impact on the amount of carbon monoxide and hydrocarbons in the exhaust gas.

Devices are offered on our market, in which the fuel flowing from the tank is subjected to the action of a permanent magnetic field. Fuel, flowing through a sufficiently strong magnetic field, becomes "ordered" and "standardized" in the size of the hydrocarbon groups. As a result, it increases the evaporation surface of the atomized fuel, more thorough mixing of the drops with air, easier access to oxygen. Increasing the evaporation surface and better mixing with oxygen molecules ensures a more complete combustion of the fuel.

More complete combustion translates into greater thermal energy yield from the fuel, lower emission of toxic substances in the exhaust gas and higher efficiency of energy conversion in the engine. So you can say, that through magnetic activation, optimization of the engine operating parameters can be achieved.

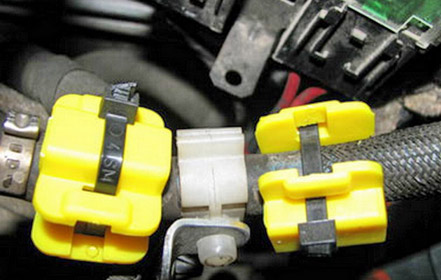

Device, which provides magnetic activation of the fuel, is popularly called a magnetizer. The magnetic activator can be mounted in a few minutes on fuel lines of any diameter, without cutting them. It can be installed in spark ignition engines with carburettor fueling,

as well as injection and compression ignition engines. It can be used in installations powered by a propane-butane mixture.

On gasoline engines with a carburetor, the fuel activator is mounted as close to the carburetor as possible. In spark ignition engines with injection fueling and compression ignition engines, apart from the fuel activator, an air activator should be installed on the line between the air filter., and the intake manifold.

To achieve the benefits of using activators, we need to understand the role of the air filter. To be burned 1 liter of petrol, the air filter must be cleaned 10 thousand liters of air. Filter contamination increases the flow resistance of this medium through the filter, consequently the engine consumes the same amount of fuel, but for less air. Excess fuel is not used. Thus, the content of toxic substances in the exhaust gas increases, Then, deposits on the parts of the combustion chamber build up rapidly. The result of this situation is a decrease in the power and performance of the car and an accelerated wear of the engine. Therefore, maintaining the efficiency of the air filter and the cleanliness of the filtering system significantly affects the cost of operating the vehicle.

The factory air filter replacement intervals must be adhered to. It is unacceptable to clean this filter in any way to extend its service life.

-

Recent Posts

Categories

Tags

- security

- Bora

- Camry

- Carina

- Escort

- rims

- Fiat

- Fiesta

- Ford

- armchair

- car seats

- Galloper

- brake

- Hyundai

- Ibiza

- magnetyzer

- Maverick

- Mazda

- body

- Nissan

- Octavia

- heating

- fuel

- seatbelts

- Peugeot

- hub

- joints

- Point

- Rover

- Saab

- Samurai

- lockers

- Seat

- Sierra

- engine

- Skoda

- lubrication

- Subaru

- Suzuki

- Toyota

- tuning

- Volkswagen

- Volvo

- buy

- bearing

-

Popular articles

Translation

Bookmarks