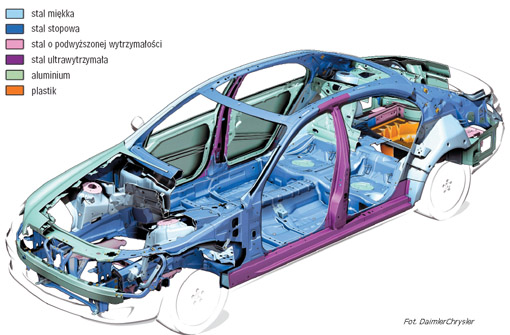

The most common body structures in practice are self-supporting shell structures. They are lightweight, cheap to produce, allow free development of usable space and low floor level routing. Part of the subtractable plating elements, np. door, Cover, front fenders, does not participate in the transfer of loads, so they can be made of plastic. Because they are usually fastened via bolted connections, can be easily replaced in case of damage. The body of the Lancia Lambda car from 1922 r. In the mid-years 30. self-supporting steel bodies have already been used by m.in. by Citroen, Opel and Renault. After the Second World War, this concept finally prevailed., especially after the spread of electronic computational techniques. The longitudinal frames have remained faithful to American companies for the longest time. It was thanks to this construction of cars that almost annual presentations of new models in years were real. 50/60. De facto after depreciation and wear of the dies, which happened quickly due to long production runs, only the elements of the outer sheathing were replaced, keeping the frame, hull, suspension components and mechanical assemblies.

The most common body structures in practice are self-supporting shell structures. They are lightweight, cheap to produce, allow free development of usable space and low floor level routing. Part of the subtractable plating elements, np. door, Cover, front fenders, does not participate in the transfer of loads, so they can be made of plastic. Because they are usually fastened via bolted connections, can be easily replaced in case of damage. The body of the Lancia Lambda car from 1922 r. In the mid-years 30. self-supporting steel bodies have already been used by m.in. by Citroen, Opel and Renault. After the Second World War, this concept finally prevailed., especially after the spread of electronic computational techniques. The longitudinal frames have remained faithful to American companies for the longest time. It was thanks to this construction of cars that almost annual presentations of new models in years were real. 50/60. De facto after depreciation and wear of the dies, which happened quickly due to long production runs, only the elements of the outer sheathing were replaced, keeping the frame, hull, suspension components and mechanical assemblies.

Main components of the shell self-supporting body (Citroen Xantia) this:

– floor plate with the necessary reinforcements;

– front part with front module (the so-called. frontend), stringers (girders) and frontal septum;

– side walls;

– based on the A pillars, B and C (sometimes D, np. in a station wagon body) roof with window blanks;

– the rear part with the rear strap.

Door, covers and usually screw-on front fenders can be made of plastic. Depending on the size and level of modernity of the car, the number of tin stampings varies from 100 do 400, the number of welding points can reach 5000, and the total length of the welds of width 1,0-1,8 mm is 120-200 m. The thickness of the sheets used is usually 0,75-1,0 mm.

Body shell of a compact class passenger car (Volkswagen Golf IV) is rigid, durable and provides a high level of passive safety. In its construction, m.in were used.: front stringers with graduated stiffness, unified floor plate, common to many models ‘ of the same concern (Audi A3 and TT, Seat Leon and Toledo, Skoda Octavia, VW Bora and Beetle), strengthening of thresholds, roof crossbar connecting the central pillars, massive rear posts with large cross-section and laser sheet metal joining technology.