The detonation combustion sensor is an additional device, improving the control of the fuel combustion process in the engine.

The detonation combustion sensor is an additional device, improving the control of the fuel combustion process in the engine.

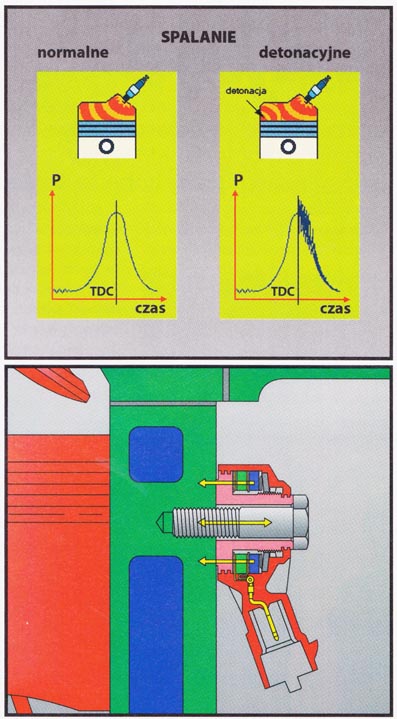

The course of pressure in the combustion chamber as a function of time. On the left – combustion properly initiated by a spark of a spark plug, characterized by mild pressure changes. On the right – detonation burning, sudden pressure surges due to microblasts in various places in the combustion chamber

Its use is not necessary, it is not found in cheap and simple constructions. In typical, for more advanced solutions, one sensor is used, which determines the occurrence of detonation in any cylinder. The control unit can assign them to a specific cylinder, by comparing the time of detonation and the time of ignition in this cylinder. A single sensor is mounted on the outside of the engine hull or head, usually between the second and third cylinders (in 4-cylinder motors). In drive units with enhanced parameters and extensive control (sequence control) more sensors are used, e.g.. evenly or on each cylinder, which allows for more precise individual control of the ignition point.

Correct combustion of the mixture in the cylinder initiated by the spark generated at the right moment on the electrodes of the spark plug, that the pressure wave in the combustion chamber smoothly increases. This pressure increase does not cause a shock wave and strong vibrations in the engine hull.

If the combustion process is disturbed, e.g.. poor quality of fuel, engine overheating, unit is overloaded or spark plug is defective, ignition of the mixture occurs accidentally in several places in the combustion chamber, at minimal intervals. Each such ignition generates a sonic microwave, which hits the cylinder walls and causes vibrations of varying amplitude, propagating through the hull of the power unit. These blows are known as detonations or knocking, and they are perceived from the outside as characteristic knocks, sometimes referred to incorrectly as valve ringing

The detonation combustion sensor responds to these vibrations, generating electrical signals that are processed by the engine control unit when they occur. They cause the reaction of delaying ignition until the detonation combustion ceases (loss of sensor signal), when the ignition control accelerates the ignition again, to return to the point of detonation. The ignition advance setting therefore oscillates around the point of detonation. It happens so, because combustion of the mixture in the engine gives the best results (best fuel efficiency), when the mixture ignites at the limit of detonation. The detonation combustion sensor is, to put it simply, a kind of piezoelectric microphone. Sound wave, caused by a sharp increase in combustion pressure, propagating through the engine block, acts mechanically on a material with piezoelectric properties placed inside the sensor housing. The effect of this action is the appearance of voltage on the electrodes surrounding the material. The voltage amplitude is proportional to the detonation energy in the cylinder.

Because the detonation sensor responds to vibration, must be properly tuned to the function performed. The point is, so that it does not react to the valves hitting the valve seats, the camshaft cams on the tappets or other vibrations caused by the operation of the mechanical components of the engine. Tuning is achieved by appropriately preloading the piezoelectric material of the sensor, this is achieved by tightening the sensor to the fuselage with a bolt of strictly defined stiffness and a torque carefully selected for a specific type of engine.

The failure of the detonation combustion sensor is difficult to detect and always causes the ignition control to switch to the emergency operation mode (ignition retardation up to the limit specified by the engineer as safe).

The clearest signs of damage to the detonation sensor are:

• ignition of the engine control failure light

• saving the fault code in the driver's memory (the code can only be read using a diagnostic device)

• noticeable reduction in the performance of the power unit, so low engine dynamics

• increased fuel consumption.

The cause of the malfunction of the knock sensor circuit is usually problems with the electrical system (corroded contacts, increased contact resistance), bad attachment to the power unit block (tightening torque too low, stretched bolt). It is also possible for the plate of piezoelectric material inside the sensor to break due to the motor overheating, improper assembly or damage to it during other work on the engine. Defective sensor cannot be repaired. When replacing or reassembling it, it is also recommended to use a new fastening screw.